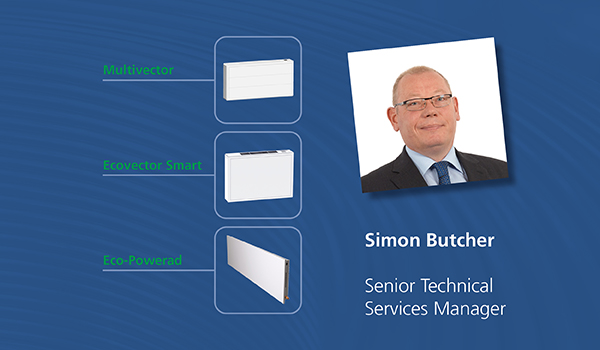

Simon Butcher Senior Technical Services Manager, Smith’s Environmental Products

Whilst many social housing providers such as housing associations and local councils are already in the throes of installing low carbon heating solutions, most privately owned homes have yet to address the issue. A significant area of concern is the heating of our existing housing stock and there can be a range of difficult questions to consider not least what type of heat emitter to use, which we will try to address in this article. One thing we can all be certain of is the development of further regulation to drive carbon reduction within the built environment generally and more specifically our homes. It is expected that homes in 2050 will have carbon emissions up to 80% less than those built to current building regulations. So, we have aspiration backed up by a regulatory framework, which means we have no choice but to embrace the challenge.

It would be remiss of me to not mention new build properties, as many of the challenges are similar. However, the drivers are very different, and the decision-making process moves from the homeowner and into the developers’ hands. Compliance with Part L1 means the carrot has been left behind and the big stick is now being used to gain the highest degree of compliance. Part L will require a reduction of 31% in carbon emissions compared to homes built to current standards. With low temperature heating systems being required, heat pumps are expected to become prolific and therefore demand for emitters that work well under such conditions ever more sought after.

Will the radiators still provide enough heat when I have a heat pump installed?

Many existing dwellings have heating systems where the flow temperature could be as high as 80oC, although more typically 70oC. When we consider the operating temperatures of systems using heat pumps, their flow temperatures tend to range from 45oC and can often modulate down as low as 35oC. When a comparison is made with the same size radiator at differing system temperatures as described, radiator output can drop by half. It is possible that existing radiators were sufficiently oversized originally, but this would be far from common place. In many situations, radiators will need to be replaced by either larger ones that take up more wall space or using triple panel radiators that extend further into the room. Were the wall space or projection of a radiator out from the wall exceeds the available space an alternative heat emitter will be needed.

Would underfloor heating be better?

Underfloor heating although possible in existing dwellings has many disadvantages. It will almost certainly be highly disruptive in an occupied home, as floor screeds are lifted or routed. In many cases the cost of such work makes it prohibitive. Whilst working well in buildings designed with underfloor heating in mind, it can be sluggish in reacting to the ever-changing UK climate. Choice of floor coverings can also impact the performance, with carpets inhibiting the heat transfer into the room.

What other heat emitter options do I have?

Fan convectors provide a very good alternative to radiators or underfloor heating. Modern fan convectors provide very low noise levels such as NR25, which would be difficult to hear and suitable for bedrooms.

What else makes fan convectors a good choice for heat pumps?

There are many shapes and sizes to choose from and you would find they are generally far more compact than a radiator producing the same output. Fan convectors mechanically force air movement within a room and as such you will find a far more evenly spread of heat, leading to greater comfort conditions. Fan convectors are very responsive to demand, and tests have proven they can heat a room quicker than a radiator. Whereas radiators operating on low temperature systems will not generate the same convective air currents.

There is also a wide range of choices in terms of control. Smith’s EcoPowerad can be used with either standard or smart TRV’s. However, the Smith’s Multivector and Ecovector low levels units can be fitted with Smith’s Smart controls. In effect each unit is an individual zone with time, temperature, and fan speed control. With the ability to run on higher fan speeds intermittently heated rooms can have the temperature raised in a timely manner. Having moved from standard TRV’s and using Smart controls I’m currently saving a further 10% on my energy bills.

Fan convectors are low water content appliances, although they do require a higher flow rate. The lower water content can contribute to greater system efficiency as there is less water to heat, providing up to a 10% saving.

smithsep.co.uk | 01245 324900 | sales@smithsep.co.uk